BWT 2000W Blu-ray Laser is on the market

BWT 2000W Blu-ray Laser is on the market

Recently, BWT has launched a 2000W Blu-ray laser to boost a new era of Blu-ray applications.

As an application-level landing product, the new 2000W Blu-ray product uses a 600μm core diameter, a single-module 105μm optical fiber output, and a power of 250W, which is comparable to the industry-leading level . The launch of Blu-ray's new products will comprehensively improve users' experience in hybrid welding, release productivity to a greater extent, and improve processing efficiency.

Figure 1: Kaplein 2000W blue laser

Figure 1: Kaplein 2000W blue laser

Blue-ray lasers are important equipment in the fields of industry, medical treatment, lighting, etc., especially providing a variety of processing solutions for industrial high-reflective material welding.

In 2015, German semiconductor laser manufacturer DILAS (acquired by Coherent) and Shimadzu Corporation of Japan successively launched low-power blue-ray lasers, but due to low power, they could not be directly applied and did not receive much attention. With the development of the times, lightweight equipment has higher requirements on materials , and high-reflective materials such as copper have entered the stage , which puts forward new requirements for laser welding. Traditional fiber lasers will produce splashes and bubbles when welding highly reflective materials, but blue-ray products can well avoid this situation, which directly promotes the development and upgrading of high-power blue-ray lasers.

Caplin is an early domestic enterprise that develops blue-ray lasers and realizes industrial applications. Since the first industrial-grade blue-ray semiconductor laser was launched in 2018, Kaplein Blu-ray products have undergone several iterations, and the product system power has been increased to hundreds of watts (500W 330μm), kilowatts (1000W 330μm), until the high power 2000W 600μm; A single module achieves 105μm optical fiber output, and the power is also upgraded from 50W to 250W, which is a leader in the industry.

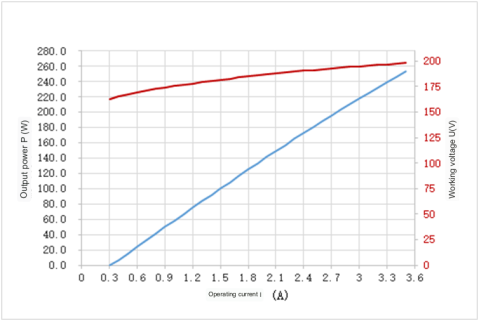

Figure 2: PIV curve of 250W Blu-ray module

Compared with the old models, Caplin 2000W Blu-ray products have new improvements. Firstly, the power of a single module in the product is increased to 250W ; secondly, the 600μm core diameter output pushes the brightness of the fiber to the first-class level in the industry . These changes, while improving processing efficiency and quality, also address user pain points, continuously improve user experience, and continue to shape new forms of industrial manufacturing in applications such as composite welding and cladding .

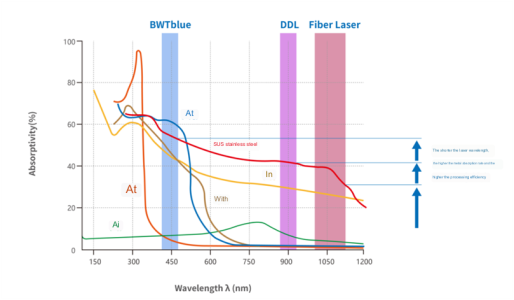

Blu-ray lasers are mainly used in the new energy industry. With the rapid development of this industry, the demand for pure copper welding is increasing day by day. It is understood that compared with the infrared wavelength of standard fiber lasers, the absorption rate of copper at blue wavelengths at room temperature can reach 45% (about 5 times or more), which makes blue lasers attractive in the field of power batteries . For example, for components such as copper hairpin motors and aluminum casings of power batteries, blue lasers can achieve near-perfect composite welding.

However, traditional high-power fiber laser welding is prone to blast holes and spatter, which affects the quality and appearance of welds, and can also cause pollution and damage to laser optical components. Compared with the infrared laser processing effect, the blue laser not only hardly introduces porosity and spatter in the welding and cladding process , but also ensures a smooth appearance and avoids secondary processing ; it can also realize the welding of pure copper with lower power lasers, and the welding process Stable melting pool, energy saving and environmental protection . Therefore, in the field of highly reflective metal material processing, blue lasers have highlighted their absolute advantages.

Figure 3: Absorption Spectrum of Common Metal Materials & Room Temperature

With the upgrade of the power of Keplin blue laser to 2000W, users can face the fast-growing new energy vehicle battery production, metal 3D printing and consumer electronics market applications , by using blue light and infrared hybrid welding, with faster processing speed and higher Excellent processing quality, create key advantages, and better meet the high-volume demand of the commercial market.

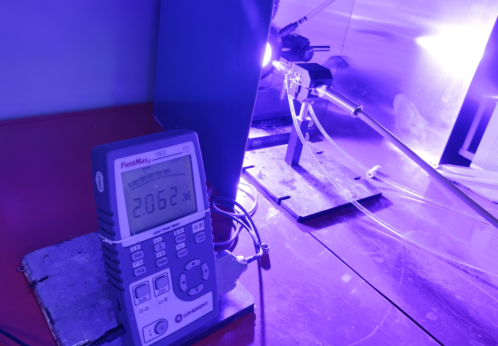

Figure 4: 2000W Blu-ray product power test results

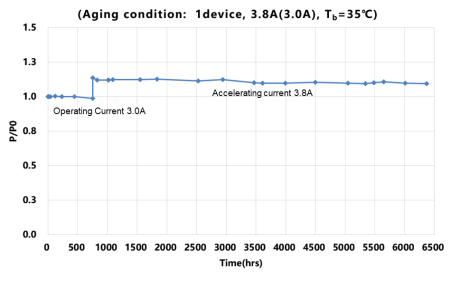

In order to let users have a more intuitive understanding of the reliability of Caplin Blu-ray products, Figure 5 shows the life data of Caplin Blu-ray products. The power change rate of the module is less than 5% after 6500 hours of aging. It can be seen that, due to its unique packaging technology, Caplin has guaranteed the advantages of high power stability , product life and reliability of Blu-ray products.

Figure 5: Caplin Blu-ray module life data

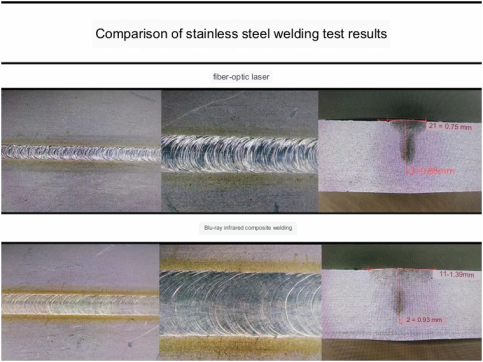

Tested by the Kaplein Industrial Application Laboratory, the blue laser has shown obvious advantages in composite welding of copper, stainless steel and other materials. As shown in Figure 6, compared with the fiber laser, the blue-light infrared composite welding effect is more delicate and smooth, flat and beautiful , with less spatter and greater penetration .

Figure 6: Comparison of blue light and infrared composite welding effects

The video shows that when the Kaplein blue laser is used in hairpin welding, the process is stable and reliable, the absorption rate is high, and the spot size is large; the molten pool is formed quickly and the processing time is short.