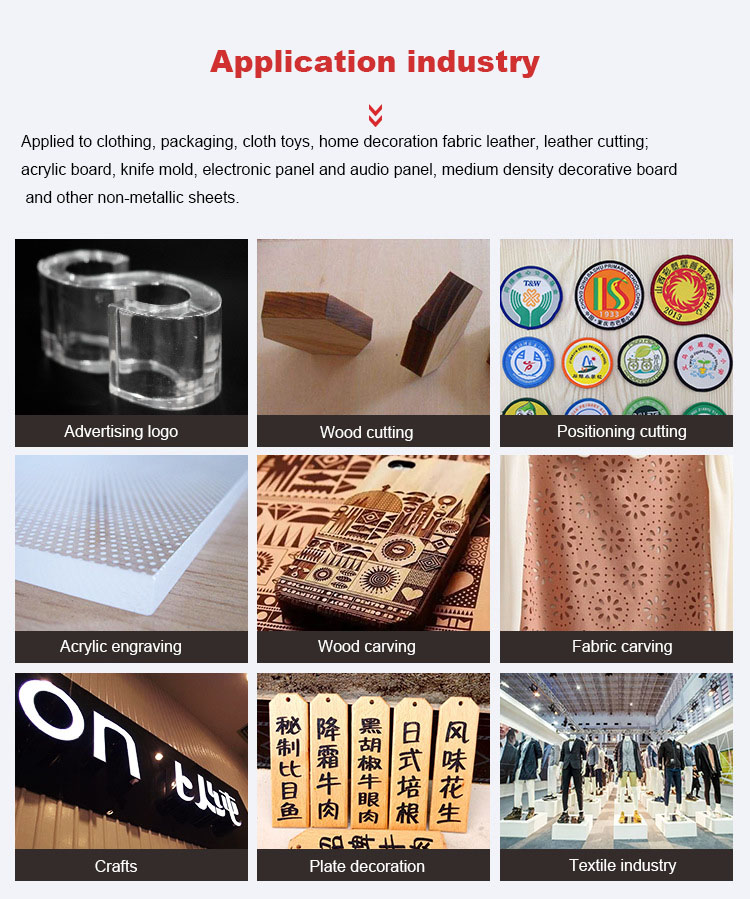

1. The processing precision of the ultraviolet laser cutting machine is high, the minimum focus spot can reach below 10 microns, the processing position is high precision, and the cutting gap is small;

2. The thermal impact is small, the degree of carbonization of the processed materials is low, no carbonization is visible to the naked eye, and some materials are completely free of carbonization;

3. It can process any graphics, the software imports graphics, and the camera points and grabs the rake for processing, without the need for mold opening operation, which is very simple and the method is simple and easy to understand;

4. The cutting edge is smooth, neat and without burrs;

5. Easy to automate, high flexibility, one machine with multiple functions;

6. High flexibility and wide range of applications;

7. The equipment has no consumables and no special fixtures, which is conducive to improving product competitiveness.

| Power |

15/20/25/30/35/40W |

| Working range | 400*400mm optional |

| Laser lifetime | ≥30,000 hours |

| Cutting speed | 10-5000m/s |

| Repeated Accuracy | 0.001mm |

| type of cooling | circulating water cooling |

| Power Requirement | 220V/AC 50HZ |

UV LASER CUTTING MACHINE

it has higher precision and better cutting effect than traditional long-wavelength cutting machines.

The use of high-energy laser sources and precise control of the laser beam can effectively increase the processing speed and obtain more accurate processing results.