1. High efficiency:

Fiber lasers have high electro-optic conversion efficiency and a conversion efficiency of more than 30%. The low-power fiber laser does not need to be equipped with a chiller, and is air-cooled, which greatly saves power consumption during operation, saves operating costs, and achieves maximum production efficiency.

2. Low cost:

The laser only needs electric energy when working, there is no lens in the laser generator, no maintenance is required during use, small size, easy to integrate, no start-up time, high power density, and better effect;

3. Excellent beam quality:

The output wavelength of the fiber laser is 1.064 microns, which is 1/10 of the wavelength of CO2, which is beneficial to the absorption of metal materials. The focus point is smaller, the cutting line is thinner, the cutting is smoother, the appearance is beautiful, no deformation, the work efficiency is higher, and the processing quality is better.

4. Simple operation:

It can process various graphics and texts in time, making the design of the mechanical system very simple and easy to integrate with robots or multi-dimensional workbenches; it can be divided into multiple devices through optical fibers, divided into multiple channels, and multiple units work at the same time. Function expansion is convenient, and upgrade is convenient and simple.

5. Save material and work space:

The fiber laser cutting machine has high cutting precision and high dimensional precision. The incision is smooth, clean, burr-free, and the material loss is extremely small; using computer programming, it can cut products of different shapes, and can achieve zero tail cutting, which improves the utilization rate of materials.

The fiber laser is small in size, light in weight, the working position can be moved, and the floor space is small.

6. Safety and environmental protection:

The fiber laser cutting machine cuts plates with low noise and less waste. It has a dust collector with low dust pollution, and the machine tool is also fully enclosed with high safety, which greatly improves the working environment.

| Power | 800w/2200w |

| Working range | 300x500mm/600x800mm |

| Cutting line width | 0.05-0.15mm(Depend on the material) |

| Cutting speed | 5000-25000mm/min(Depend on the material) |

| Cutting accuracy | 0.01mm |

| Cutting pressure | 1.2-2.8Mpa |

| Rated power | 10/18KW |

| Power requirement | 220/380V/AC 32/60A |

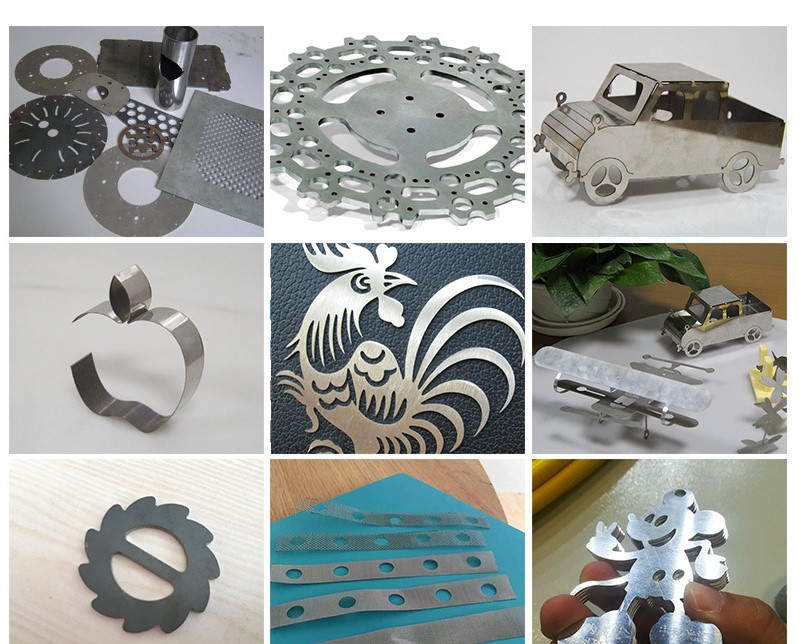

FIBER LASER CUTTING MACHINE

It can save investment costs, save materials, reduce work difficulty, and improve work efficiency.

At the same time, it can improve production and processing quality and make cutting accuracy higher.